Civil Structures Assessment

Context

Throughout their useful life, civil structures, whether metallic or concrete, have failures in their performance related to design failures, construction problems, operational issues of the surroundings and/or lack of maintenance.

Several factors can impact the conditions of durability, functionality and stability of the structures, such as the action of weather, mechanical stresses or impacts, wear and vibration, among others. To meet minimum quality requirements – such as breakage safety, in-service performance and the ability to withstand the environmental influences predicted and defined in the project – structures must undergo inspection and maintenance cycles, preventing anomalies from impairing their performance and, at a more advanced stage, compromising their safety.

Thus, it is necessary to carry out thorough inspections and, when necessary, field and/or laboratory tests to detect faults and identify their causes and respective degradation mechanisms, allowing the definition of recovery plans and methodologies and, in critical cases, the elaboration of structural reinforcement projects.

The GIA-O&M area has a specialized team and equipment necessary to carry out inspections, tests, evaluation and diagnosis on the conditions of durability and functionality of the structures, as well as the provision of technical specifications and budget for recovery services.

For the analysis of the stability of the structures, we carried out field surveys to reconstitution the structure geometry, tests for characterization of materials and monitoring to identify the natural frequency of the structure – activities necessary for the elaboration of mathematical model through finite element software, aiming to analyze the load capacity, operational readjustment and / or compliance with technical standards.

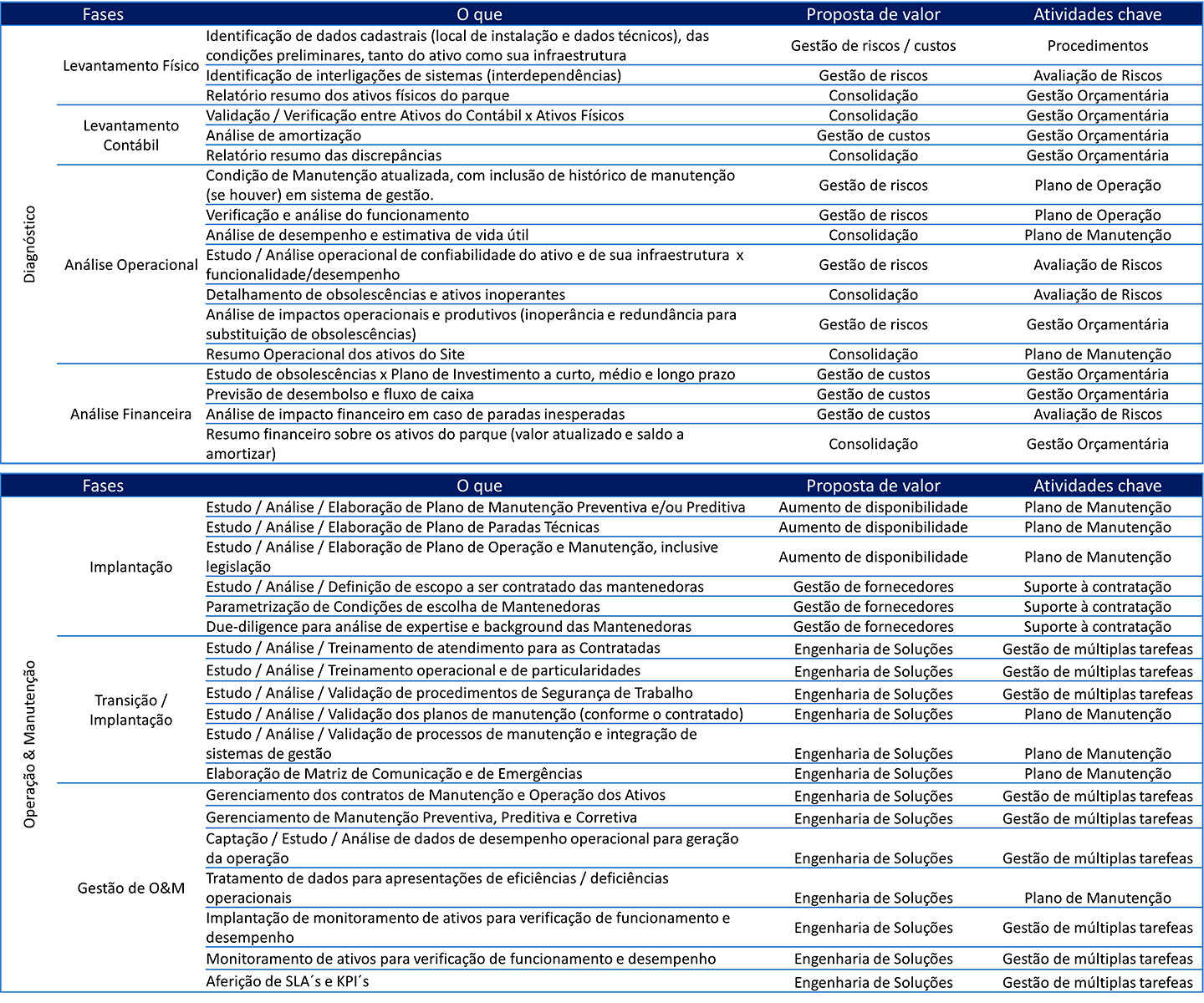

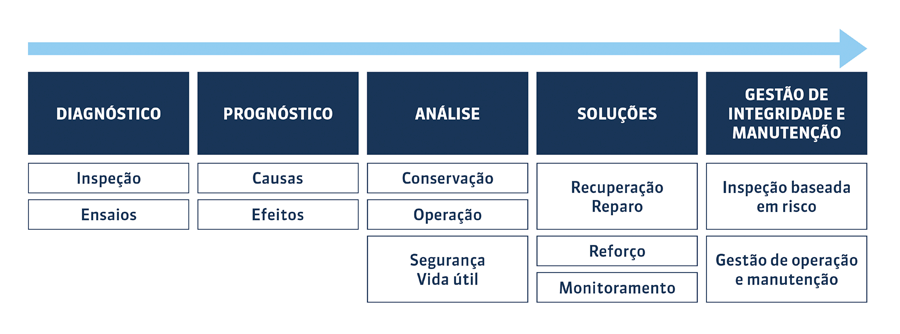

Standard Flow of Action in the Area

Aiming to provide a more efficient management of physical assets, the GIA-O&M area also implements and customization of the asset maintenance management system. Currently, a new platform integrated with BIM for the management of special works of art is also under development.

Services Offered

Integrity

There are several ways to perform a structure assessment to determine your integrity:

Inspections

The objective of an inspection is to identify the existing damages and risks in a given structure in such a way as to enable the diagnosis / prognosis to be elaborated and, based on them, to perform the analysis of existing conditions based on a GUT matrix (severity, urgency and trend), ultimately generating the preparation of maintenance plans in the short, medium and long term, as well as the recovery and/or protection methodologies that are necessary to return the structure normal operating conditions and service life.

Inspections can be carried out with the aid of high-resolution cameras, drones, scaffolding, access platforms and rappelling, among others. The following are the types of inspections:

– Cadastral inspection:

inspection with the objective of performing a first risk classification and prioritization among an asset park.

– Routine inspection:

inspection performed according to predefined periodicity in the client’s asset management plan, aiming at monitoring the pathological picture.

– Special inspection:

detailed inspection of the structure, identifying each of the existing anomalies focusing on the maintenance plan and subsequent contracting of the recovery works.

From the inspections and, when necessary, according to the results of the tests performed, concremat’s technical team produces a series of products that will support its customers in decision making. See below some of them:

» Issuance of technical report containing the conditions of durability and functionality.

» Development of recovery and/or protection methodologies.

» Determination of alert levels and priorities of interventions.

» Preparation of short, medium and long-term maintenance plans.

» Preparation of budget for the execution of the recovery / repair works.

The area also performs other assessments and generates more specific products according to the needs of the customer and the nature of the project.

Tests

The use of tests in inspections of structures decreases subjectivity and, consequently, improves the results obtained in the analysis of the structures. The tests help in the identification of the mechanisms of deterioration and make it possible to analyze the degree of wear of the structure.

From a first analysis of existing damage, our team defines the necessary tests, which can be, among others:

» Identification of reinforcements and verification of the thickness of concrete cover by pacometry.

» Determination of the carbonation depth of the concrete and the covering of the reinforcements.

» Verification of the corrosion potential of the reinforcements.

» Verification of the homogeneity of the concrete.

» Verification of the electrical resistivity of the concrete.

» Determination of the compressive strength (fck) of the concrete.

» Determination of the physical-chemical characteristics of the concrete.

» Determination of chloride and sulphur ion content.

» Determination of Alkali-Aggregate reaction – RAA.

» Penetrating liquid and/or magnetic particles.

» Measurement of loss of thickness of reinforcement and/or metallic elements.

» Ultrasound for the determination of weld ing irregularities and metal elements.

» Static and dynamic load tests.

From the inspections and, when necessary, according to the results of the tests performed, concremat’s technical team produces a series of products that will support its customers in decision making. See below some of them:

» Issuance of technical report containing the conditions of durability and functionality.

» Development of recovery and/or protection methodologies.

» Determination of alert levels and priorities of interventions.

» Preparation of short, medium and long-term maintenance plans.

» Preparation of budget for the execution of the recovery / repair works.

The area also performs other assessments and generates more specific products according to the needs of the customer and the nature of the project.

Load Capacity

The main reasons that lead to the need to verify the load capacity of the structure are aggressive and advanced pathological condition, changes in the use of the structure, adequacy and compliance with current standards.

In this step, through mathematical finite element models, the structure is modeled and evaluated for deformations, state, service limits (ELS), and last limit state (ELU).

Unfortunately, one does not have the storage culture of the original projects, as well as the interventions carried out over time. In this way, it is necessary to reconstitute the structure first.

The activities carried out in this type of work are:

» Manual geometric survey and/or laser scanner.

» Reconstitution / conference of the original project.

» Numerical modeling for checking load capacity and strength.

» Dynamic monitoring for calibration of the mathematical model.

» Issuance of technical report containing the stability conditions.

» Determination of safety coefficients and priorities of interventions.

» Development of structural reinforcement projects.

» Preparation of a budget for the implementation of structural reinforcement works.

Dams

For dams (accumulation or tailings) structures, more specific technical activities are required. Currently there is a technical standardization that defines premises and requirements that the owners of the assets must perform. Our teams are able to carry out the following activities:

» Regular inspection.

» Multidisciplinary special inspection.

» Carrying out the reading campaigns of the existing instrumentation.

» Checks of instrumentation alert levels.

» Analysis of instrumentation behavior.

» Stability analysis.

» Preparation of the Dam Safety Plan (PSB).

» Preparation of the Periodic Dam Safety Review (RPSB).

» Preparation of the Emergency Care Plan (PAE).